So I was watching this video and the thought dawned on me, "This is me when I finally lose my friggin' mind!"

https://www.youtube.com/watch?v=q_YZX1SgZ5Y

https://www.youtube.com/watch?v=q_YZX1SgZ5Y

Definitely would be the first on my block with something like that. But don't tell the neighbors. I can't see myself wanting to explain that one to anybody.

Definitely would be the first on my block with something like that. But don't tell the neighbors. I can't see myself wanting to explain that one to anybody.Sheesh, not as simple as I had hoped. There are different TYPES of lasers, as well as different power ranges, and different methods of engraving. Some are better for engraving metals (and only some metals) than others. Of course, the more power the better, but like anything else, the best tools for a job are usually the most expensive. Honestly, I don't need this THAT much to spend multiple thousands of dollars on a machine. But there are some that are comparatively modestly priced that MIGHT do what I want.

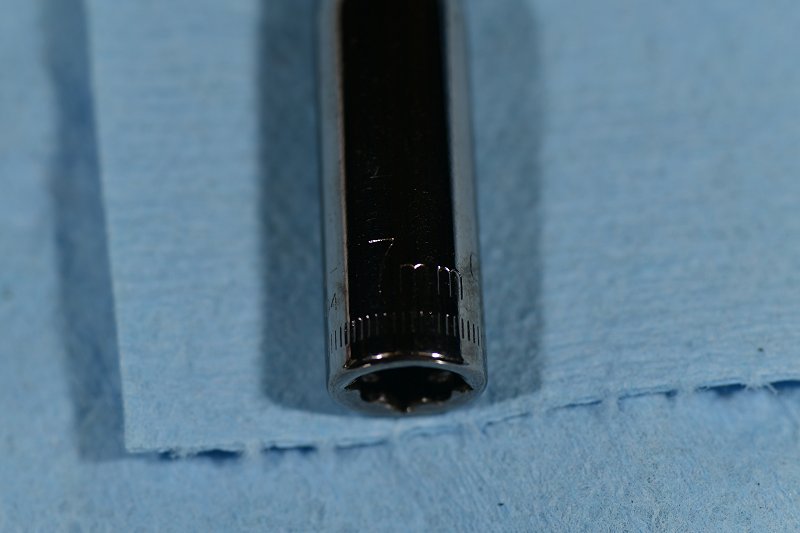

One I looked at, that I found most intriguing, is called the LaserPecker.Definitely would be the first on my block with something like that. But don't tell the neighbors. I can't see myself wanting to explain that one to anybody.